Tip

An interactive online version of this notebook is available, which can be

accessed via

Alternatively, you may download this notebook and run it offline.

Attention

You are viewing this notebook on the latest version of the documentation, where these notebooks may not be compatible with the stable release of PyBaMM since they can contain features that are not yet released. We recommend viewing these notebooks from the stable version of the documentation. To install the latest version of PyBaMM that is compatible with the latest notebooks, build PyBaMM from source.

Modelling lithium plating in PyBaMM#

This notebook shows how PyBaMM [8] can be used to model both reversible and irreversible lithium plating.

[1]:

%pip install "pybamm[plot,cite]" -q # install PyBaMM if it is not installed

import pybamm

import os

os.chdir(pybamm.__path__[0] + "/..")

The Doyle-Fuller-Newman model [3] is upgraded with three different lithium plating models. Model 1 contains the reversible lithium plating model of O’Kane et al. [5]. Model 2 contains the same model but with the lithium stripping capability removed, making the plating irreversible. Model 3 contains the updated partially reversible plating of O’Kane et al. [6]. The parameters are taken from Chen et al.’s investigation [2] of an LG M50 cell.

[2]:

# choose models

plating_options = ["reversible", "irreversible", "partially reversible"]

models = {

option: pybamm.lithium_ion.DFN(options={"lithium plating": option}, name=option)

for option in plating_options

}

# pick parameters

parameter_values = pybamm.ParameterValues("OKane2022")

parameter_values.update({"Ambient temperature [K]": 268.15})

parameter_values.update({"Upper voltage cut-off [V]": 4.21})

# parameter_values.update({"Lithium plating kinetic rate constant [m.s-1]": 1E-9})

parameter_values.update({"Lithium plating transfer coefficient": 0.5})

parameter_values.update({"Dead lithium decay constant [s-1]": 1e-4})

A series of simple fast charging experiments based on those of Ren et al. [7] is defined here. We first initialise the model at 0% SoC by performing a C/20 discharge (see more details on how to initialise a model from a simulation in this notebook).

[3]:

# specify experiments

pybamm.citations.register("Ren2018")

s = pybamm.step.string

experiment_discharge = pybamm.Experiment(

[

(

s("Discharge at C/20 until 2.5 V", period="10 minutes"),

s("Rest for 1 hour", period="3 minutes"),

),

]

)

sims_discharge = []

for model in models.values():

sim_discharge = pybamm.Simulation(

model, parameter_values=parameter_values, experiment=experiment_discharge

)

sol_discharge = sim_discharge.solve(calc_esoh=False)

model.set_initial_conditions_from(sol_discharge, inplace=True)

sims_discharge.append(sim_discharge)

And we can now define the different experiments to charge at different C-rates.

[4]:

C_rates = ["2C", "1C", "C/2", "C/4", "C/8"]

experiments = {}

for C_rate in C_rates:

experiments[C_rate] = pybamm.Experiment(

[

(

f"Charge at {C_rate} until 4.2 V",

"Hold at 4.2 V until C/20",

"Rest for 1 hour",

)

]

)

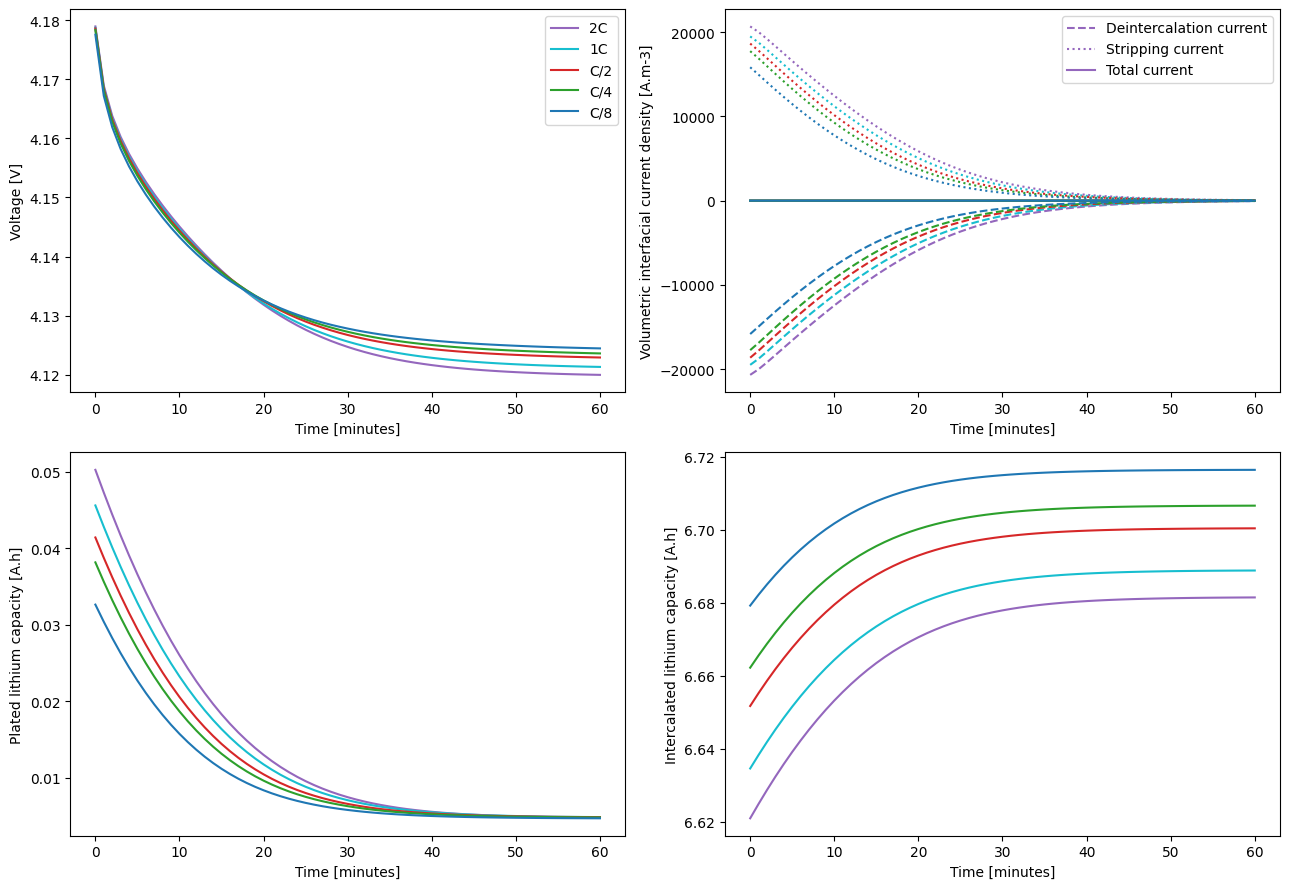

Solve the reversible plating model first. The default CasADi [1] solver is used here.

[5]:

def define_and_solve_sims(model, experiments, parameter_values):

sims = {}

for C_rate, experiment in experiments.items():

sim = pybamm.Simulation(

model, experiment=experiment, parameter_values=parameter_values

)

sim.solve(calc_esoh=False)

sims[C_rate] = sim

return sims

sims_reversible = define_and_solve_sims(

models["reversible"], experiments, parameter_values

)

[6]:

colors = ["tab:purple", "tab:cyan", "tab:red", "tab:green", "tab:blue"]

linestyles = ["dashed", "dotted", "solid"]

param = models["reversible"].param

A = parameter_values.evaluate(param.L_y * param.L_z)

F = parameter_values.evaluate(param.F)

L_n = parameter_values.evaluate(param.n.L)

currents = [

"X-averaged negative electrode volumetric interfacial current density [A.m-3]",

"X-averaged negative electrode lithium plating volumetric interfacial current density [A.m-3]",

"Sum of x-averaged negative electrode volumetric interfacial current densities [A.m-3]",

]

def plot(sims):

import matplotlib.pyplot as plt

fig, axs = plt.subplots(2, 2, figsize=(13, 9))

for (C_rate, sim), color in zip(sims.items(), colors):

# Isolate final equilibration phase

sol = sim.solution.cycles[0].steps[2]

# Voltage vs time

t = sol["Time [min]"].entries

t = t - t[0]

V = sol["Voltage [V]"].entries

axs[0, 0].plot(t, V, color=color, linestyle="solid", label=C_rate)

# Currents

for current, ls in zip(currents, linestyles):

j = sol[current].entries

axs[0, 1].plot(t, j, color=color, linestyle=ls)

# Plated lithium capacity

Q_Li = sol["Loss of capacity to negative lithium plating [A.h]"].entries

axs[1, 0].plot(t, Q_Li, color=color, linestyle="solid")

# Capacity vs time

Q_main = (

sol["Negative electrode volume-averaged concentration [mol.m-3]"].entries

* F

* A

* L_n

/ 3600

)

axs[1, 1].plot(t, Q_main, color=color, linestyle="solid")

axs[0, 0].legend()

axs[0, 0].set_ylabel("Voltage [V]")

axs[0, 1].set_ylabel("Volumetric interfacial current density [A.m-3]")

axs[0, 1].legend(("Deintercalation current", "Stripping current", "Total current"))

axs[1, 0].set_ylabel("Plated lithium capacity [A.h]")

axs[1, 1].set_ylabel("Intercalated lithium capacity [A.h]")

for ax in axs.flat:

ax.set_xlabel("Time [minutes]")

fig.tight_layout()

return fig, axs

plot(sims_reversible);

The results show both similarities and differences with those of Ren et al. [7]. Notably, unlike Ren et al., this model uses equations [5] that result in a small but finite amount of plated lithium being present in the steady state.

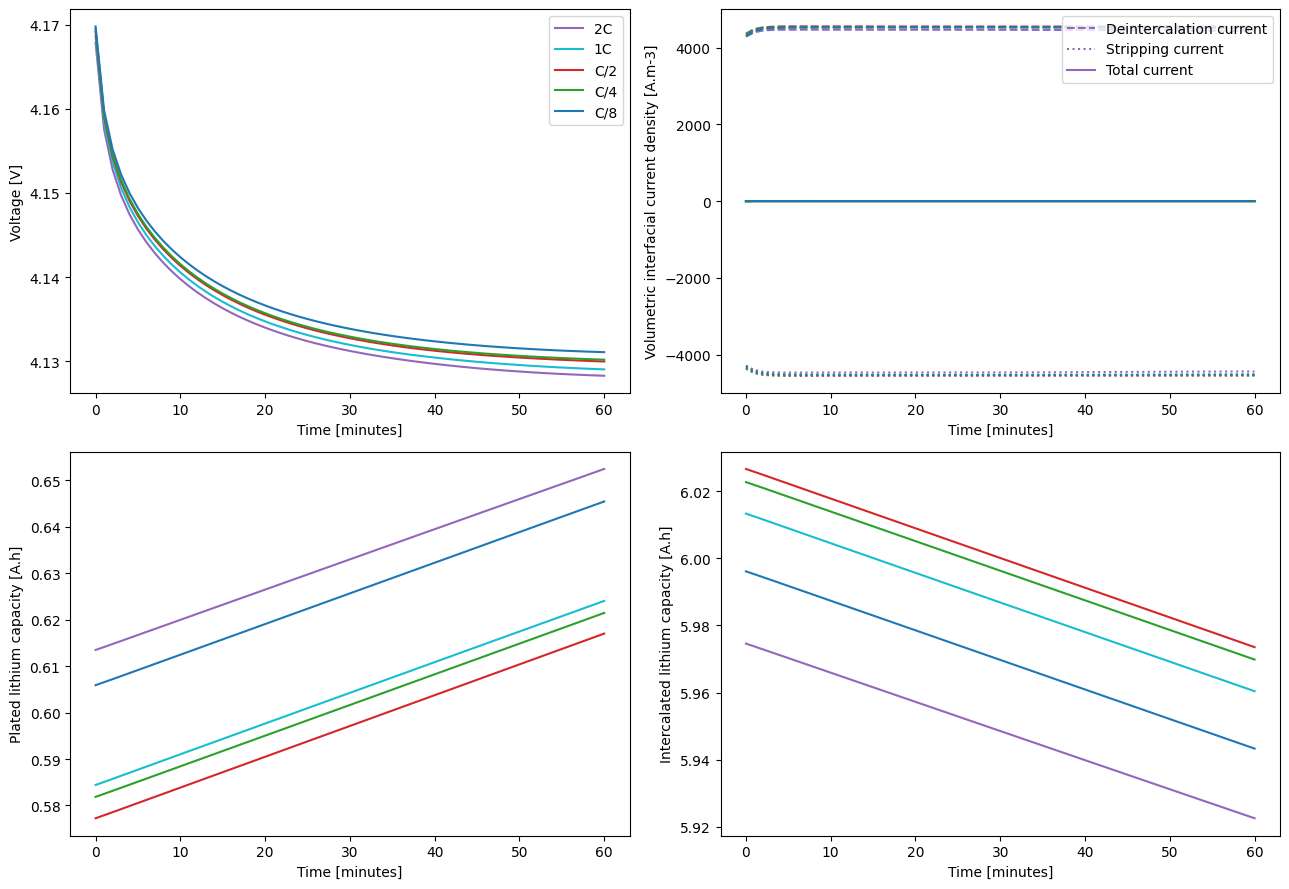

Now solve the irreversible plating model and see how it compares.

[7]:

sims_irreversible = define_and_solve_sims(

models["irreversible"], experiments, parameter_values

)

[8]:

plot(sims_irreversible);

Unlike in the reversible case, there is no steady state and the capacity degrades quickly. The lithium inventory decreases by around 40 mAh in just an hour, which is unrealistic. The low temperature fast charge simulations are run one more time, with the partially reversible plating model.

[9]:

sims_partially_reversible = define_and_solve_sims(

models["partially reversible"], experiments, parameter_values

)

[10]:

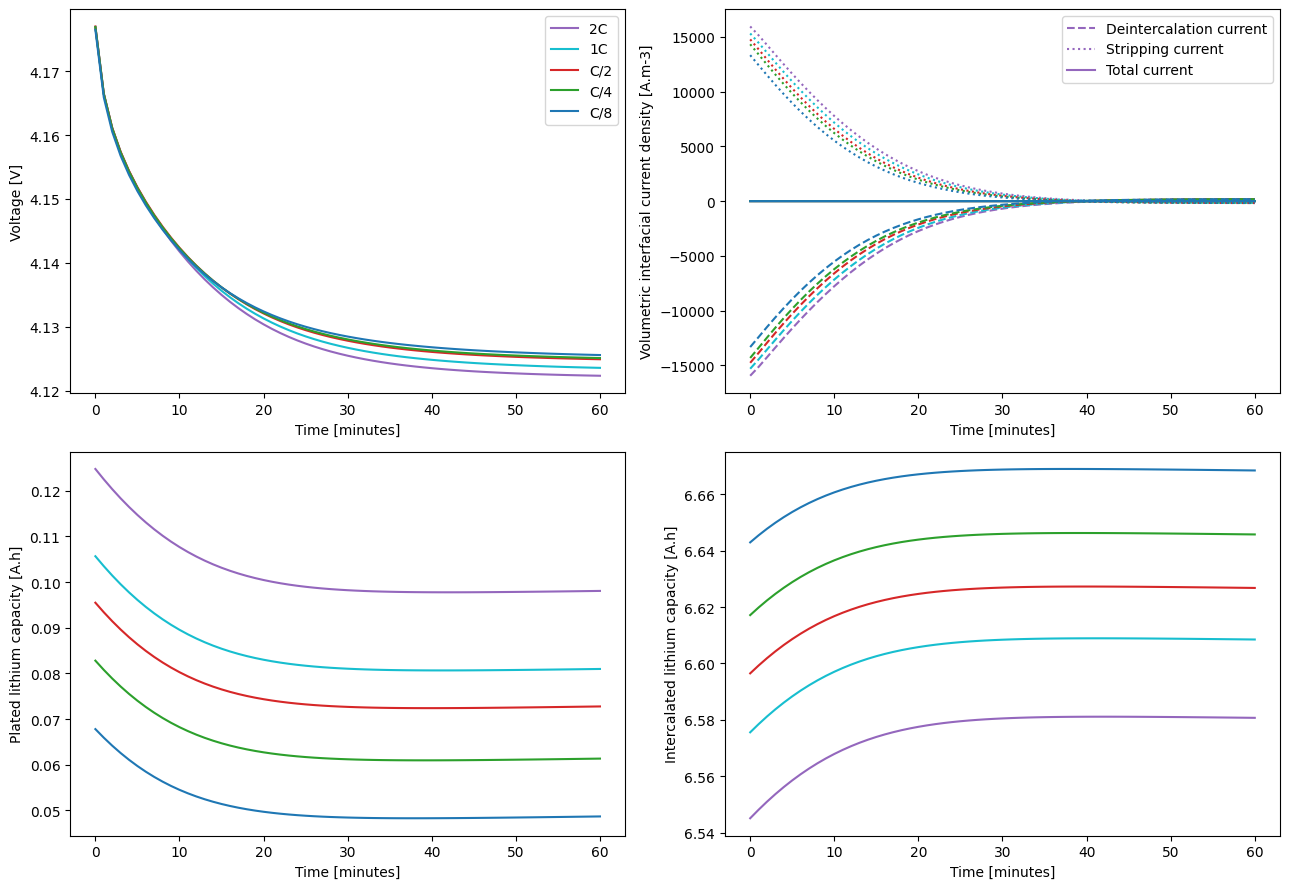

plot(sims_partially_reversible);

The partially reversible plating model has features of both the reversible and irreversible models, which is reflected in the results. The plated lithium capacity decreases with time as lithium is reversibly stripped, but the final plated lithium capacity now depends on charge rate, indicating that some lithium was irreversibly plated during charge.

References#

[11]:

pybamm.print_citations()

[1] Joel A. E. Andersson, Joris Gillis, Greg Horn, James B. Rawlings, and Moritz Diehl. CasADi – A software framework for nonlinear optimization and optimal control. Mathematical Programming Computation, 11(1):1–36, 2019. doi:10.1007/s12532-018-0139-4.

[2] Chang-Hui Chen, Ferran Brosa Planella, Kieran O'Regan, Dominika Gastol, W. Dhammika Widanage, and Emma Kendrick. Development of Experimental Techniques for Parameterization of Multi-scale Lithium-ion Battery Models. Journal of The Electrochemical Society, 167(8):080534, 2020. doi:10.1149/1945-7111/ab9050.

[3] Marc Doyle, Thomas F. Fuller, and John Newman. Modeling of galvanostatic charge and discharge of the lithium/polymer/insertion cell. Journal of the Electrochemical society, 140(6):1526–1533, 1993. doi:10.1149/1.2221597.

[4] Charles R. Harris, K. Jarrod Millman, Stéfan J. van der Walt, Ralf Gommers, Pauli Virtanen, David Cournapeau, Eric Wieser, Julian Taylor, Sebastian Berg, Nathaniel J. Smith, and others. Array programming with NumPy. Nature, 585(7825):357–362, 2020. doi:10.1038/s41586-020-2649-2.

[5] Simon E. J. O'Kane, Ian D. Campbell, Mohamed W. J. Marzook, Gregory J. Offer, and Monica Marinescu. Physical origin of the differential voltage minimum associated with lithium plating in li-ion batteries. Journal of The Electrochemical Society, 167(9):090540, may 2020. URL: https://doi.org/10.1149/1945-7111/ab90ac, doi:10.1149/1945-7111/ab90ac.

[6] Simon E. J. O'Kane, Weilong Ai, Ganesh Madabattula, Diego Alonso-Alvarez, Robert Timms, Valentin Sulzer, Jacqueline Sophie Edge, Billy Wu, Gregory J. Offer, and Monica Marinescu. Lithium-ion battery degradation: how to model it. Phys. Chem. Chem. Phys., 24:7909-7922, 2022. URL: http://dx.doi.org/10.1039/D2CP00417H, doi:10.1039/D2CP00417H.

[7] Dongsheng Ren, Kandler Smith, Dongxu Guo, Xuebing Han, Xuning Feng, Languang Lu, and Minggao Ouyang. Investigation of lithium plating-stripping process in li-ion batteries at low temperature using an electrochemical model. Journal of the Electrochemistry Society, 165:A2167-A2178, 2018. doi:10.1149/2.0661810jes.

[8] Valentin Sulzer, Scott G. Marquis, Robert Timms, Martin Robinson, and S. Jon Chapman. Python Battery Mathematical Modelling (PyBaMM). Journal of Open Research Software, 9(1):14, 2021. doi:10.5334/jors.309.