Tip

An interactive online version of this notebook is available, which can be

accessed via

Alternatively, you may download this notebook and run it offline.

Attention

You are viewing this notebook on the latest version of the documentation, where these notebooks may not be compatible with the stable release of PyBaMM since they can contain features that are not yet released. We recommend viewing these notebooks from the stable version of the documentation. To install the latest version of PyBaMM that is compatible with the latest notebooks, build PyBaMM from source.

Modelling coupled degradation mechanisms in PyBaMM#

This notebook shows how to set up a PyBaMM model in which many degradation mechanisms run at the same time and interact with one another.

[1]:

%pip install "pybamm[plot,cite]" -q # install PyBaMM if it is not installed

import pybamm

import matplotlib.pyplot as plt

[notice] A new release of pip available: 22.3.1 -> 23.1.2

[notice] To update, run: pip install --upgrade pip

Note: you may need to restart the kernel to use updated packages.

O’Kane et al. [10] modelled four coupled degradation mechanisms: SEI growth, lithium plating, particle cracking and stress-driven loss of active material. The “SEI on cracks” option couples SEI growth and particle cracking by allowing SEI to grow on the cracks. The “partially reversible” option for lithium plating allows the SEI to influence the irreversible component of plating using a function in the OKane2022 parameter file. Particle cracking and stress-driven loss of active material are coupled by default because the stress-strain relations inside the particles are an input for both.

[2]:

model = pybamm.lithium_ion.DFN(

{

"SEI": "solvent-diffusion limited",

"SEI porosity change": "true",

"lithium plating": "partially reversible",

"lithium plating porosity change": "true", # alias for "SEI porosity change"

"particle mechanics": ("swelling and cracking", "swelling only"),

"SEI on cracks": "true",

"loss of active material": "stress-driven",

"calculate discharge energy": "true", # for compatibility with older PyBaMM versions

}

)

Depending on the parameter set being used, the particle cracking model can require a large number of mesh points inside the particles to be numerically stable.

[3]:

param = pybamm.ParameterValues("OKane2022")

var_pts = {

"x_n": 5, # negative electrode

"x_s": 5, # separator

"x_p": 5, # positive electrode

"r_n": 30, # negative particle

"r_p": 30, # positive particle

}

Define a cycling protocol and solve. The protocol from O’Kane et al. [10] is used here, except with 10 ageing cycles instead of 1000.

[4]:

cycle_number = 10

exp = pybamm.Experiment(

[

"Hold at 4.2 V until C/100 (5 minute period)",

"Rest for 4 hours (5 minute period)",

"Discharge at 0.1C until 2.5 V (5 minute period)", # initial capacity check

"Charge at 0.3C until 4.2 V (5 minute period)",

"Hold at 4.2 V until C/100 (5 minute period)",

]

+ [

(

"Discharge at 1C until 2.5 V", # ageing cycles

"Charge at 0.3C until 4.2 V (5 minute period)",

"Hold at 4.2 V until C/100 (5 minute period)",

)

]

* cycle_number

+ ["Discharge at 0.1C until 2.5 V (5 minute period)"], # final capacity check

)

sim = pybamm.Simulation(model, parameter_values=param, experiment=exp, var_pts=var_pts)

sol = sim.solve()

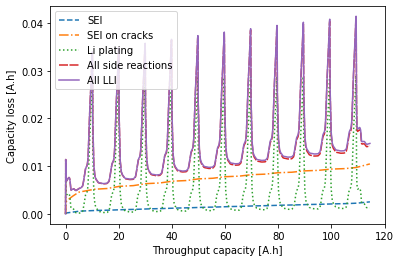

Three of the degradation mechanisms - SEI, lithium plating and SEI on cracks - cause loss of lithium inventory (LLI). Plotting the different contributions to LLI against throughput capacity as opposed to cycle number allows them to be considered as continuous variables as opposed to discrete ones.

[5]:

Qt = sol["Throughput capacity [A.h]"].entries

Q_SEI = sol["Loss of capacity to negative SEI [A.h]"].entries

Q_SEI_cr = sol["Loss of capacity to negative SEI on cracks [A.h]"].entries

Q_plating = sol["Loss of capacity to negative lithium plating [A.h]"].entries

Q_side = sol["Total capacity lost to side reactions [A.h]"].entries

Q_LLI = (

sol["Total lithium lost [mol]"].entries * 96485.3 / 3600

) # convert from mol to A.h

plt.figure()

plt.plot(Qt, Q_SEI, label="SEI", linestyle="dashed")

plt.plot(Qt, Q_SEI_cr, label="SEI on cracks", linestyle="dashdot")

plt.plot(Qt, Q_plating, label="Li plating", linestyle="dotted")

plt.plot(Qt, Q_side, label="All side reactions", linestyle=(0, (6, 1)))

plt.plot(Qt, Q_LLI, label="All LLI")

plt.xlabel("Throughput capacity [A.h]")

plt.ylabel("Capacity loss [A.h]")

plt.legend()

plt.show()

The capacity loss over 10 cycles is so small that the reversible component of the lithium plating is has a larger effect than all the irreversible mechanisms combined. Most of the irreversible capacity fade that does occur is caused by SEI on cracks.

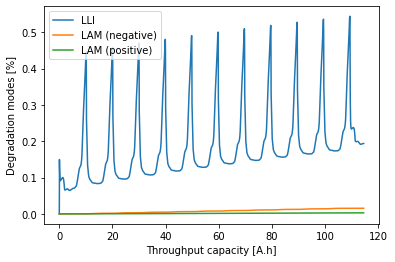

The stress-driven loss of active material (LAM) mechanism [10,11] is also included, so the three main degradation modes - LLI and LAM in each electrode - can be plotted and compared.

[6]:

Qt = sol["Throughput capacity [A.h]"].entries

LLI = sol["Loss of lithium inventory [%]"].entries

LAM_neg = sol["Loss of active material in negative electrode [%]"].entries

LAM_pos = sol["Loss of active material in positive electrode [%]"].entries

plt.figure()

plt.plot(Qt, LLI, label="LLI")

plt.plot(Qt, LAM_neg, label="LAM (negative)")

plt.plot(Qt, LAM_pos, label="LAM (positive)")

plt.xlabel("Throughput capacity [A.h]")

plt.ylabel("Degradation modes [%]")

plt.legend()

plt.show()

Both the reversible and irreversible components of LLI are far greater than LAM for this parameter set.

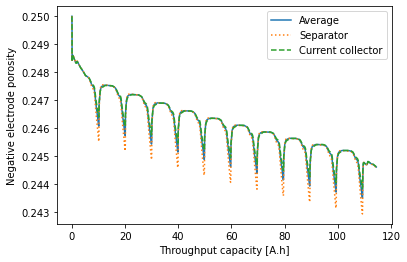

A key internal variable is the porosity. Pore clogging by SEI, lithium plating and other means can trigger other degradation mechanisms and reduce the rate capability of the cell. If the porosity reaches zero, the cell becomes completely unusable and PyBaMM will terminate the simulation.

[7]:

eps_neg_avg = sol["X-averaged negative electrode porosity"].entries

eps_neg_sep = sol["Negative electrode porosity"].entries[-1, :]

eps_neg_CC = sol["Negative electrode porosity"].entries[0, :]

plt.figure()

plt.plot(Qt, eps_neg_avg, label="Average")

plt.plot(Qt, eps_neg_sep, label="Separator", linestyle="dotted")

plt.plot(Qt, eps_neg_CC, label="Current collector", linestyle="dashed")

plt.xlabel("Throughput capacity [A.h]")

plt.ylabel("Negative electrode porosity")

plt.legend()

plt.show()

If you want to see some serious degradation, try re-running the simulation with more ageing cycles, or using param.update({}) to increase the degradation parameters beyond the ranges considered by O’Kane et al. [10]

[8]:

pybamm.print_citations()

[1] Weilong Ai, Ludwig Kraft, Johannes Sturm, Andreas Jossen, and Billy Wu. Electrochemical thermal-mechanical modelling of stress inhomogeneity in lithium-ion pouch cells. Journal of The Electrochemical Society, 167(1):013512, 2019. doi:10.1149/2.0122001JES.

[2] Joel A. E. Andersson, Joris Gillis, Greg Horn, James B. Rawlings, and Moritz Diehl. CasADi – A software framework for nonlinear optimization and optimal control. Mathematical Programming Computation, 11(1):1–36, 2019. doi:10.1007/s12532-018-0139-4.

[3] Chang-Hui Chen, Ferran Brosa Planella, Kieran O'Regan, Dominika Gastol, W. Dhammika Widanage, and Emma Kendrick. Development of Experimental Techniques for Parameterization of Multi-scale Lithium-ion Battery Models. Journal of The Electrochemical Society, 167(8):080534, 2020. doi:10.1149/1945-7111/ab9050.

[4] Rutooj Deshpande, Mark Verbrugge, Yang-Tse Cheng, John Wang, and Ping Liu. Battery cycle life prediction with coupled chemical degradation and fatigue mechanics. Journal of the Electrochemical Society, 159(10):A1730, 2012. doi:10.1149/2.049210jes.

[5] Marc Doyle, Thomas F. Fuller, and John Newman. Modeling of galvanostatic charge and discharge of the lithium/polymer/insertion cell. Journal of the Electrochemical society, 140(6):1526–1533, 1993. doi:10.1149/1.2221597.

[6] Charles R. Harris, K. Jarrod Millman, Stéfan J. van der Walt, Ralf Gommers, Pauli Virtanen, David Cournapeau, Eric Wieser, Julian Taylor, Sebastian Berg, Nathaniel J. Smith, and others. Array programming with NumPy. Nature, 585(7825):357–362, 2020. doi:10.1038/s41586-020-2649-2.

[7] Scott G. Marquis. Long-term degradation of lithium-ion batteries. PhD thesis, University of Oxford, 2020.

[8] Peyman Mohtat, Suhak Lee, Jason B Siegel, and Anna G Stefanopoulou. Towards better estimability of electrode-specific state of health: decoding the cell expansion. Journal of Power Sources, 427:101–111, 2019.

[9] Simon E. J. O'Kane, Ian D. Campbell, Mohamed W. J. Marzook, Gregory J. Offer, and Monica Marinescu. Physical origin of the differential voltage minimum associated with lithium plating in li-ion batteries. Journal of The Electrochemical Society, 167(9):090540, may 2020. URL: https://doi.org/10.1149/1945-7111/ab90ac, doi:10.1149/1945-7111/ab90ac.

[10] Simon E. J. O'Kane, Weilong Ai, Ganesh Madabattula, Diego Alonso-Alvarez, Robert Timms, Valentin Sulzer, Jacqueline Sophie Edge, Billy Wu, Gregory J. Offer, and Monica Marinescu. Lithium-ion battery degradation: how to model it. Phys. Chem. Chem. Phys., 24:7909-7922, 2022. URL: http://dx.doi.org/10.1039/D2CP00417H, doi:10.1039/D2CP00417H.

[11] Jorn M. Reniers, Grietus Mulder, and David A. Howey. Review and performance comparison of mechanical-chemical degradation models for lithium-ion batteries. Journal of The Electrochemical Society, 166(14):A3189, 2019. doi:10.1149/2.0281914jes.

[12] Valentin Sulzer, Scott G. Marquis, Robert Timms, Martin Robinson, and S. Jon Chapman. Python Battery Mathematical Modelling (PyBaMM). Journal of Open Research Software, 9(1):14, 2021. doi:10.5334/jors.309.

[13] Pauli Virtanen, Ralf Gommers, Travis E. Oliphant, Matt Haberland, Tyler Reddy, David Cournapeau, Evgeni Burovski, Pearu Peterson, Warren Weckesser, Jonathan Bright, and others. SciPy 1.0: fundamental algorithms for scientific computing in Python. Nature Methods, 17(3):261–272, 2020. doi:10.1038/s41592-019-0686-2.

[14] Andrew Weng, Jason B Siegel, and Anna Stefanopoulou. Differential voltage analysis for battery manufacturing process control. arXiv preprint arXiv:2303.07088, 2023.