Tip

An interactive online version of this notebook is available, which can be

accessed via

Alternatively, you may download this notebook and run it offline.

Attention

You are viewing this notebook on the latest version of the documentation, where these notebooks may not be compatible with the stable release of PyBaMM since they can contain features that are not yet released. We recommend viewing these notebooks from the stable version of the documentation. To install the latest version of PyBaMM that is compatible with the latest notebooks, build PyBaMM from source.

Modelling SEI growth on particle cracks#

This notebook provides a short demonsration of how the SEI and particle mechanics submodels can be combined to simulate SEI growth on particle cracks.

[1]:

%pip install "pybamm[plot,cite]" -q # install PyBaMM if it is not installed

import pybamm

import matplotlib.pyplot as plt

[notice] A new release of pip available: 22.3.1 -> 23.0.1

[notice] To update, run: pip install --upgrade pip

Note: you may need to restart the kernel to use updated packages.

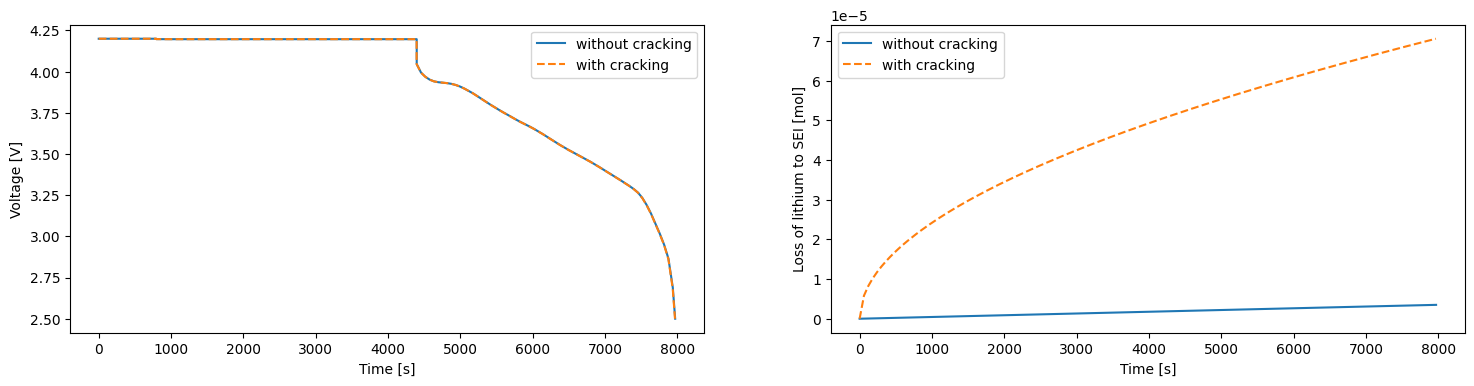

Define two models. In model1, the only degradation mechanism is solvent-diffusion limited SEI growth. model2 includes the same SEI growth mechanism but also includes particle cracking and SEI growth on the cracks. The SEI model is run twice: once on the initial surface and once on the cracks. The equations for SEI on cracks are reported by O’Kane et al. [9] To ensure a fair experiment, particle swelling is enabled in both models.

[2]:

model1 = pybamm.lithium_ion.DFN(

{"SEI": "solvent-diffusion limited", "particle mechanics": "swelling only"}

)

model2 = pybamm.lithium_ion.DFN(

{

"particle mechanics": "swelling and cracking",

"SEI": "solvent-diffusion limited",

"SEI on cracks": "true",

}

)

Depending on the parameter set being used, the particle cracking model can require a large number of mesh points inside the particles to be numerically stable.

[3]:

param = pybamm.ParameterValues("OKane2022")

var_pts = {

"x_n": 20, # negative electrode

"x_s": 20, # separator

"x_p": 20, # positive electrode

"r_n": 26, # negative particle

"r_p": 26, # positive particle

}

Solve the models with and without cracking. The steps before the 1C discharge make the model more numerically stable so fewer mesh points are required.

[4]:

exp = pybamm.Experiment(

["Hold at 4.2 V until C/100", "Rest for 1 hour", "Discharge at 1C until 2.5 V"]

)

sim1 = pybamm.Simulation(

model1, parameter_values=param, experiment=exp, var_pts=var_pts

)

sol1 = sim1.solve(calc_esoh=False)

sim2 = pybamm.Simulation(

model2, parameter_values=param, experiment=exp, var_pts=var_pts

)

sol2 = sim2.solve(calc_esoh=False)

At t = 426.174, , mxstep steps taken before reaching tout.

At t = 186.174, , mxstep steps taken before reaching tout.

At t = 430.603, , mxstep steps taken before reaching tout.

At t = 190.603, , mxstep steps taken before reaching tout.

[5]:

t1 = sol1["Time [s]"].entries

V1 = sol1["Voltage [V]"].entries

SEI1 = sol1["Loss of lithium to negative SEI [mol]"].entries

lithium_neg1 = sol1["Total lithium in negative electrode [mol]"].entries

lithium_pos1 = sol1["Total lithium in positive electrode [mol]"].entries

t2 = sol2["Time [s]"].entries

V2 = sol2["Voltage [V]"].entries

SEI2 = (

sol2["Loss of lithium to negative SEI [mol]"].entries

+ sol2["Loss of lithium to negative SEI on cracks [mol]"].entries

)

lithium_neg2 = sol2["Total lithium in negative electrode [mol]"].entries

lithium_pos2 = sol2["Total lithium in positive electrode [mol]"].entries

[6]:

fig, (ax1, ax2) = plt.subplots(1, 2, figsize=(18, 4))

ax1.plot(t1, V1, label="without cracking")

ax1.plot(t2, V2, label="with cracking")

ax1.set_xlabel("Time [s]")

ax1.set_ylabel("Voltage [V]")

ax1.legend()

ax2.plot(t1, SEI1, label="without cracking")

ax2.plot(t2, SEI2, label="with cracking")

ax2.set_xlabel("Time [s]")

ax2.set_ylabel("Loss of lithium to SEI [mol]")

ax2.legend()

plt.show()

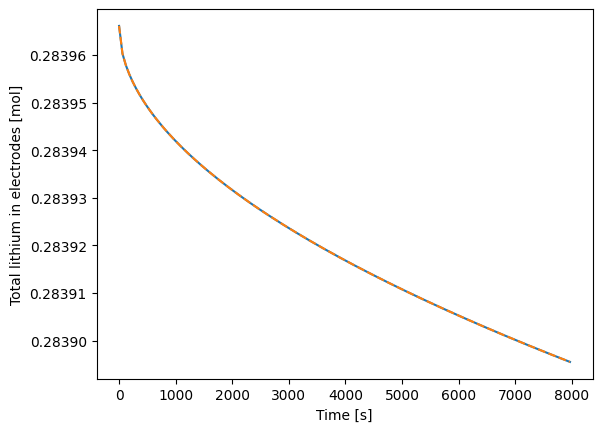

The SEI on cracks consumes far more capacity than the SEI on the initial surface, in agreement with the literature. Finally, check lithium is conserved:

[7]:

fig, ax = plt.subplots()

ax.plot(t2, lithium_neg2 + lithium_pos2)

ax.plot(t2, lithium_neg2[0] + lithium_pos2[0] - SEI2, linestyle="dashed")

ax.set_xlabel("Time [s]")

ax.set_ylabel("Total lithium in electrodes [mol]")

plt.show()

[8]:

pybamm.print_citations()

[1] Weilong Ai, Ludwig Kraft, Johannes Sturm, Andreas Jossen, and Billy Wu. Electrochemical thermal-mechanical modelling of stress inhomogeneity in lithium-ion pouch cells. Journal of The Electrochemical Society, 167(1):013512, 2019. doi:10.1149/2.0122001JES.

[2] Joel A. E. Andersson, Joris Gillis, Greg Horn, James B. Rawlings, and Moritz Diehl. CasADi – A software framework for nonlinear optimization and optimal control. Mathematical Programming Computation, 11(1):1–36, 2019. doi:10.1007/s12532-018-0139-4.

[3] Chang-Hui Chen, Ferran Brosa Planella, Kieran O'Regan, Dominika Gastol, W. Dhammika Widanage, and Emma Kendrick. Development of Experimental Techniques for Parameterization of Multi-scale Lithium-ion Battery Models. Journal of The Electrochemical Society, 167(8):080534, 2020. doi:10.1149/1945-7111/ab9050.

[4] Rutooj Deshpande, Mark Verbrugge, Yang-Tse Cheng, John Wang, and Ping Liu. Battery cycle life prediction with coupled chemical degradation and fatigue mechanics. Journal of the Electrochemical Society, 159(10):A1730, 2012. doi:10.1149/2.049210jes.

[5] Marc Doyle, Thomas F. Fuller, and John Newman. Modeling of galvanostatic charge and discharge of the lithium/polymer/insertion cell. Journal of the Electrochemical society, 140(6):1526–1533, 1993. doi:10.1149/1.2221597.

[6] Charles R. Harris, K. Jarrod Millman, Stéfan J. van der Walt, Ralf Gommers, Pauli Virtanen, David Cournapeau, Eric Wieser, Julian Taylor, Sebastian Berg, Nathaniel J. Smith, and others. Array programming with NumPy. Nature, 585(7825):357–362, 2020. doi:10.1038/s41586-020-2649-2.

[7] Scott G. Marquis. Long-term degradation of lithium-ion batteries. PhD thesis, University of Oxford, 2020.

[8] Simon E. J. O'Kane, Ian D. Campbell, Mohamed W. J. Marzook, Gregory J. Offer, and Monica Marinescu. Physical origin of the differential voltage minimum associated with lithium plating in li-ion batteries. Journal of The Electrochemical Society, 167(9):090540, may 2020. URL: https://doi.org/10.1149/1945-7111/ab90ac, doi:10.1149/1945-7111/ab90ac.

[9] Simon E. J. O'Kane, Weilong Ai, Ganesh Madabattula, Diego Alonso-Alvarez, Robert Timms, Valentin Sulzer, Jacqueline Sophie Edge, Billy Wu, Gregory J. Offer, and Monica Marinescu. Lithium-ion battery degradation: how to model it. Phys. Chem. Chem. Phys., 24:7909-7922, 2022. URL: http://dx.doi.org/10.1039/D2CP00417H, doi:10.1039/D2CP00417H.

[10] Valentin Sulzer, Scott G. Marquis, Robert Timms, Martin Robinson, and S. Jon Chapman. Python Battery Mathematical Modelling (PyBaMM). Journal of Open Research Software, 9(1):14, 2021. doi:10.5334/jors.309.